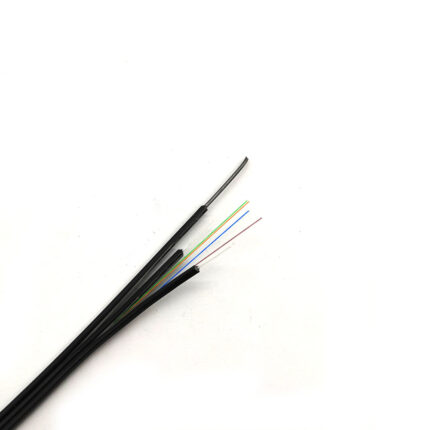

ADSS Fiber Optic Cable Description:

ADSS Fiber Optic Cable adopts loose tube cysts structure, optical fiber into the pine casing made of high modulus polyester material, waterproof casing filling compound pine casing (and filling line) around non-metallic center (FRP) to strengthen core twisted into a compact core, core within the gap filled with gel core outer extrusion polyethylene (PE) inner sheath, and then strengthen the bidirectional twisted around two layers of the function of aramid yarn, finally extrusion polyethylene (PE) coat or electrical erosion resistance (AT) your coat.

Characteristics:

·Good mechanical and temperature performance

·High strength loose tube that is hydrolysis resistant

·Special tube filling compound ensure a critical protection of fiber

·Crush resistance and flexibility

·The following measures are taken to ensure the cable watertight:

-Single Fiber Reinforced Plastic as the central strength member

-Loose tube filling compound

-100% cable core filling

-PSP enhancing moisture-proof

-Water-blocking material

Applications of ADSS Fiber Optic Cable:

ADSS (All-Dielectric Self-Supporting) fiber optic cables find applications in various industries and environments due to their unique design and characteristics:

- Telecommunications Networks: ADSS cables are commonly used for long-distance communication infrastructure, including aerial installations along power lines, railways, highways, and other utility corridors. They provide high-speed data transmission capabilities and can span significant distances without the need for additional support structures.

- Utility and Power Distribution: ADSS cables are widely deployed by utility companies for communication and monitoring purposes along electrical transmission and distribution lines. They facilitate real-time data transmission for remote monitoring, control, and diagnostics of power grid systems, enhancing operational efficiency and reliability.

- Internet Service Providers (ISPs): ADSS cables are utilized by ISPs to expand and improve broadband internet connectivity in rural and remote areas. They enable the deployment of fiber optic networks over existing utility poles, reducing the need for costly infrastructure upgrades and accelerating network expansion initiatives.

- Security and Surveillance: ADSS cables are employed for video surveillance and security applications in urban, suburban, and industrial environments. They support the transmission of high-definition video feeds over long distances, facilitating the implementation of CCTV (Closed-Circuit Television) systems for public safety, asset protection, and perimeter monitoring.

- Smart City Infrastructure: ADSS cables play a vital role in the development of smart city initiatives, providing the backbone infrastructure for various IoT (Internet of Things) sensors, smart streetlights, traffic management systems, and environmental monitoring devices. They enable seamless data connectivity and communication between different urban infrastructure components, enhancing overall city management and services.

- Industrial Automation: ADSS cables are utilized in industrial automation and control systems for communication between PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, and other industrial equipment. They support reliable and high-speed data transmission in harsh industrial environments, ensuring smooth and efficient operation of manufacturing processes and infrastructure.