GYFTY53 Fiber Cable Description:

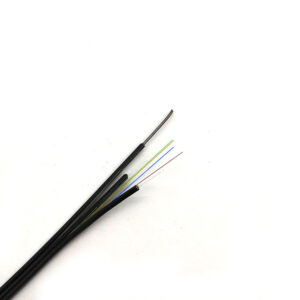

GYFTY53 Fiber Cable Single Armor Double Jackets Stranded Loose Tube FRP Strength Member Waterproof Outdoor Cable use Fiber Reinforced Plastic as central strength member to provides anti-electromagnetic interference property.

It has good mechanical properties and resist to electromagnetic interference The armor structure helps to protect the cable from rat bite and moisture proof. Double-jacket structure make cable have nice properties of moisture resistance and crush resistance. A layer of water-blocking material is applied around the cable core to prevent water ingress.

- Cable Type:

- GYFTY53 is a type of fiber optic cable designed for outdoor installations. It is commonly used for long-distance links and is suitable for both aerial and duct applications.

- Fiber Type:

- GYFTY53 cables can accommodate both single-mode and multimode fibers, providing flexibility to support various types of optical networks.

- Fiber Count:

- These cables can contain up to 288 fibers, making them suitable for high-capacity communication networks.

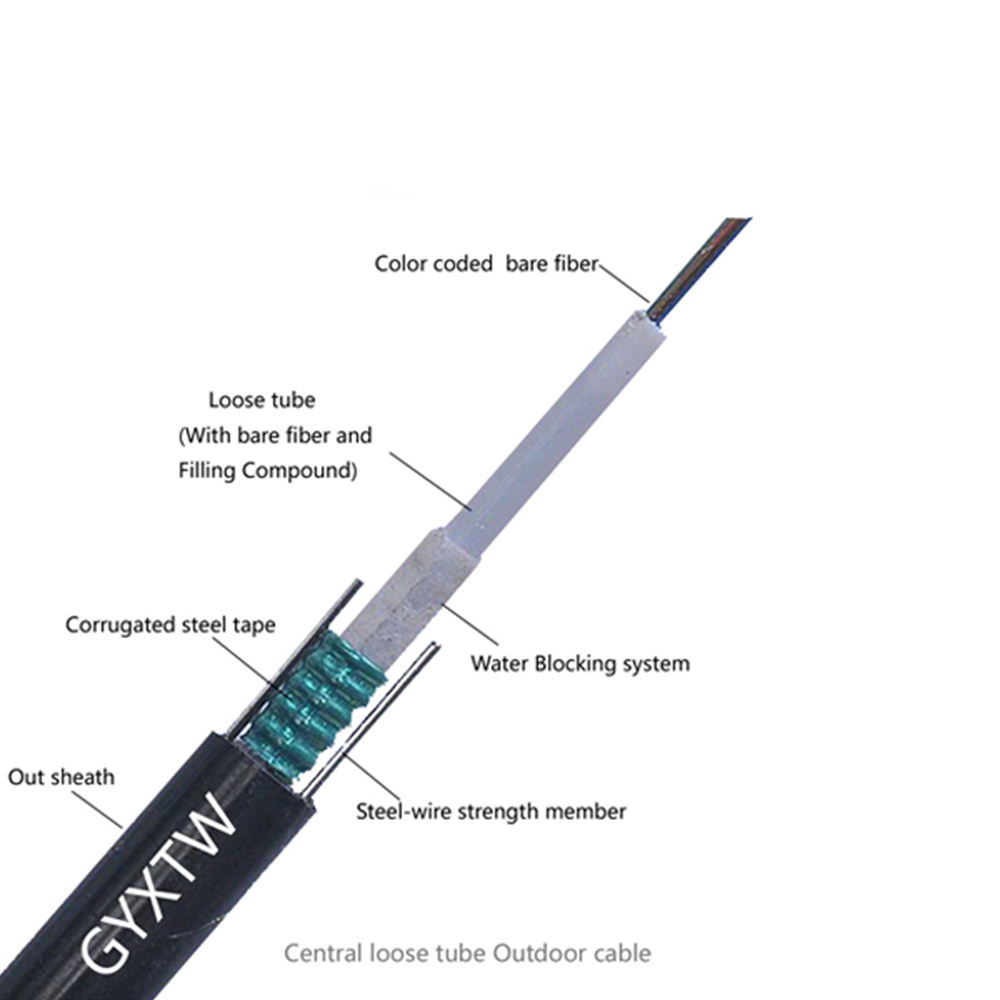

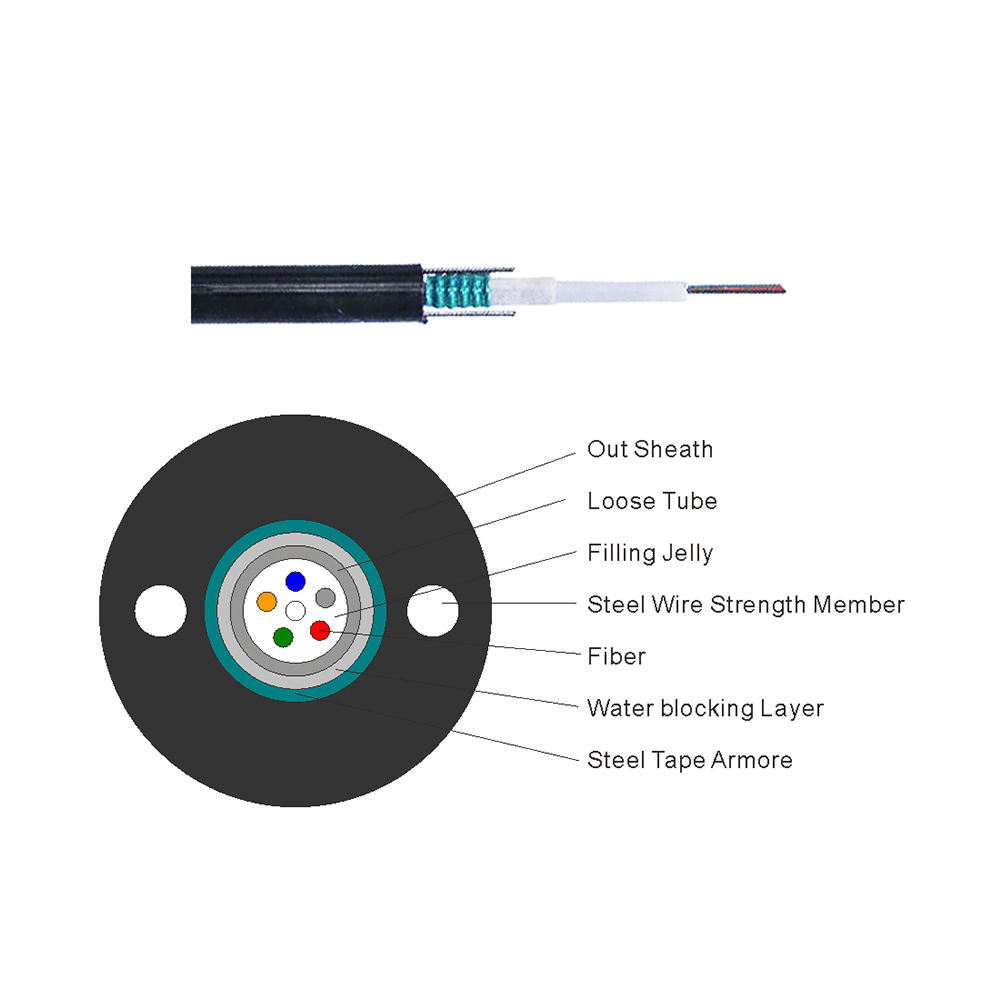

- Strength Member:

- GYFTY53 cables typically incorporate a strength member made of either Fiber Reinforced Plastic (FRP) or steel wire. This provides mechanical support and helps protect the fibers from external stresses.

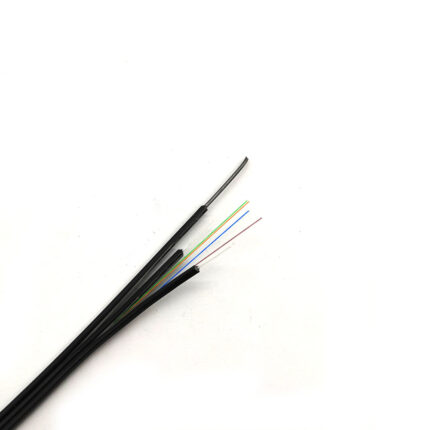

- Loose Tube Material:

- The loose tubes within GYFTY53 cables are often made of Polybutylene Terephthalate (PBT), offering excellent protection for the optical fibers against environmental factors.

- Filling Compound:

- Water-blocking gel or jelly is commonly used as a filling compound within the loose tubes to prevent water ingress and ensure long-term reliability, especially in outdoor environments.

- Armor Type:

- GYFTY53 cables feature a double-layer corrugated steel tape armor, enhancing their durability and resistance to external mechanical forces such as crushing or impact.

- Outer Sheath Material:

- The outer sheath of GYFTY53 cables is typically made of Polyethylene (PE) or Low Smoke Zero Halogen (LSZH) material, providing additional protection against environmental hazards and fire propagation.

- Application:

- These cables are designed specifically for outdoor use and are suitable for installation in aerial configurations (e.g., on poles or towers) or buried in ducts.

Features:

-

-

- GYFTY53 cables boast a high fiber count, making them ideal for densely populated areas or long-distance communication links.

- They offer excellent water-blocking properties, ensuring reliable performance even in humid or wet conditions.

- Resistant to environmental factors such as temperature fluctuations, UV radiation, and chemicals, GYFTY53 cables are built to withstand harsh outdoor conditions.

- Their durability and reliability make them a preferred choice for telecommunications and networking infrastructure projects requiring robust fiber optic connectivity.

-

Application:

- Frequent lightning area and anti electric field : The subway, tunnel

- Long-distance communication: Local trunk network & User network

- Duct and direct buried application

- Harsh environment

Specifications of GYFTY53 Fiber Cable:

| Specification | Description |

|---|---|

| Fiber Count | 53 |

| Cable Type | GYFTY (Non-metallic strength member) |

| Fiber Type | Single-mode (SM) |

| Fiber Diameter | 9/125 µm |

| Cable Diameter | 12.5 mm |

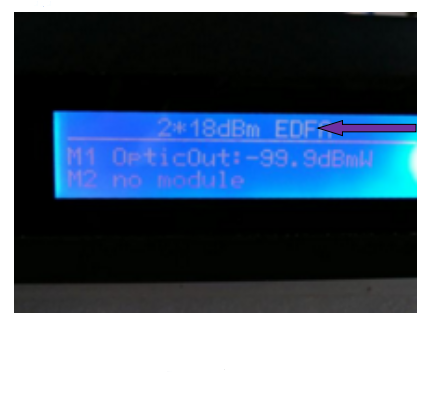

| Attenuation | ≤ 0.4 dB/km @ 1310 nm, ≤ 0.3 dB/km @ 1550 nm |

| Bandwidth | ≥ 50 GHz ·km @ 1310 nm, ≥ 100 GHz ·km @ 1550 nm |

| Operating Temperature Range | -40°C to +70°C |

| Installation Temperature Range | -20°C to +60°C |

| Tensile Strength | ≥ 600 N |

| Crush Resistance | ≥ 2200 N/100 mm |

| Bending Radius (During Installation) | ≥ 20 x Cable Diameter |

| Bending Radius (During Operation) | ≥ 10 x Cable Diameter |

| Cable Weight | Approximately 150 kg/km |

| Jacket Material | Polyethylene (PE) |

| Application | Outdoor |

| Standards | ITU-T G.652.D |