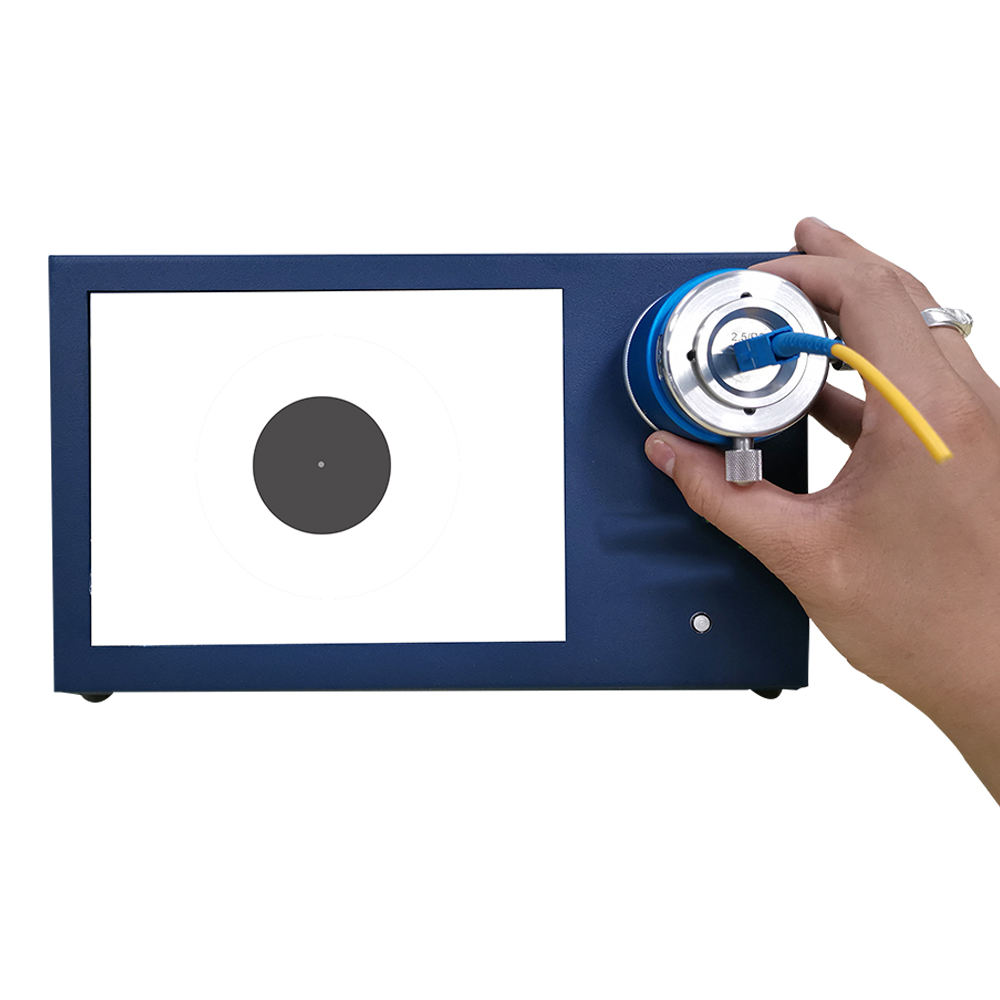

3D interferometer Display Monitor Description:

3D interferometer Display Monitor is a precise method used to test the geometry of fiber optic connector end faces. The key parameters measured include the radius of curvature (ROC) of the apex, apex offset, and fiber height. These measurements are critical for ensuring the quality and performance of fiber optic connections, as defined by the technical standards set by the International Electrotechnical Commission (IEC).

Key Parameters:

- Radius of Curvature (ROC):

- PC Type Connector: 10~25 mm

- APC Type Connector: 5~15 mm

The ROC is the radius of the sphere that best fits the curvature of the fiber end face. A well-defined ROC ensures that the fiber cores make proper contact, which is crucial for minimizing signal loss.

- Apex Offset:

- Standard Requirement: ≤ 50 μm

Apex offset is the distance between the highest point of the curved end face (apex) and the axis of the fiber. A large offset can lead to improper physical contact between fibers, increasing the risk of signal loss and reflection.

- Fiber Height:

- Standard Range: -250 nm to +250 nm

Fiber height measures the position of the fiber end face relative to the ferrule end face. The fiber can either protrude above or be recessed below the ferrule surface. Maintaining this height within the specified range ensures optimal contact and minimizes the risk of damage or signal degradation.

Importance of Measurements:

- Curvature Apex (ROC): Ensures the fiber end face has the correct shape for optimal contact, reducing signal loss and reflection.

- Apex Offset: Prevents misalignment that can cause poor physical contact and increase insertion loss.

- Fiber Height: Ensures the fiber end face is positioned correctly relative to the ferrule, preventing damage and ensuring efficient signal transmission.

Technical Standards:

According to the IEC standards, the acceptable values for these parameters are crucial for maintaining the performance and reliability of fiber optic connections. Meeting these standards ensures that the fiber optic connectors will function effectively in various applications, from telecommunications to data centers.

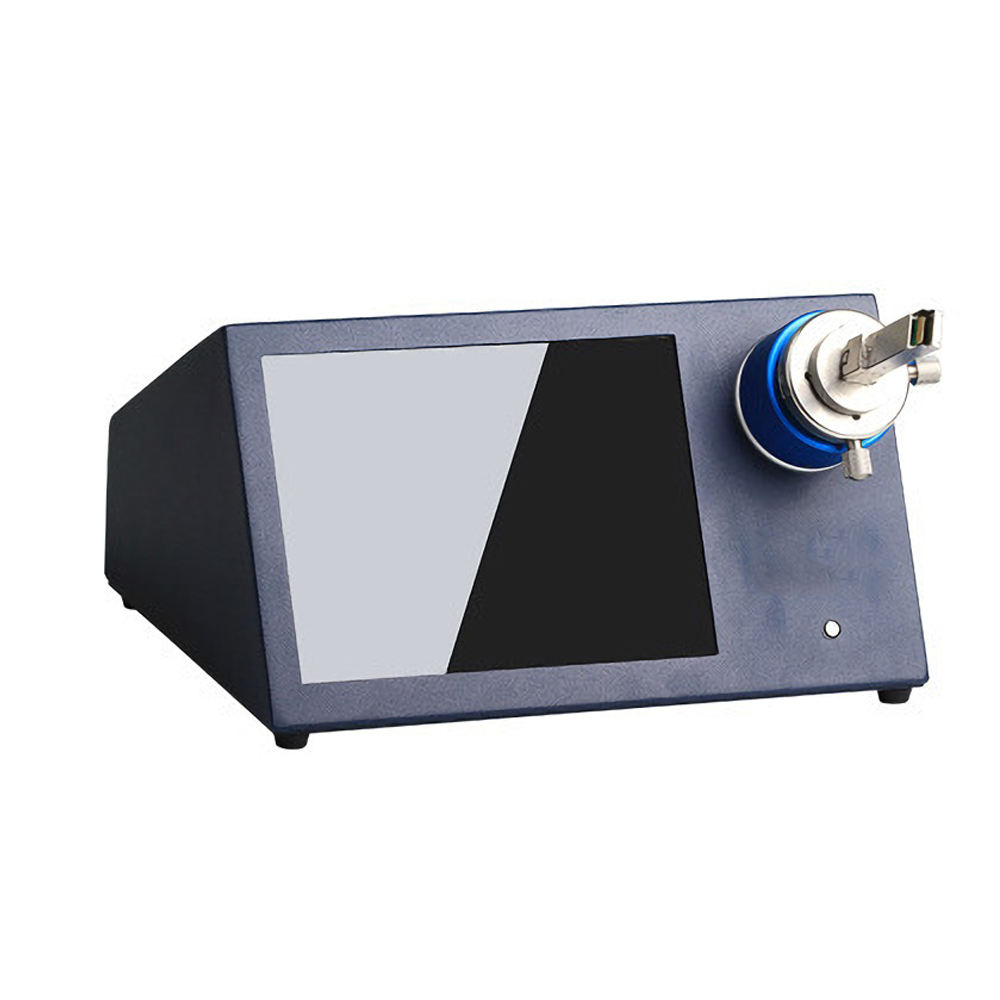

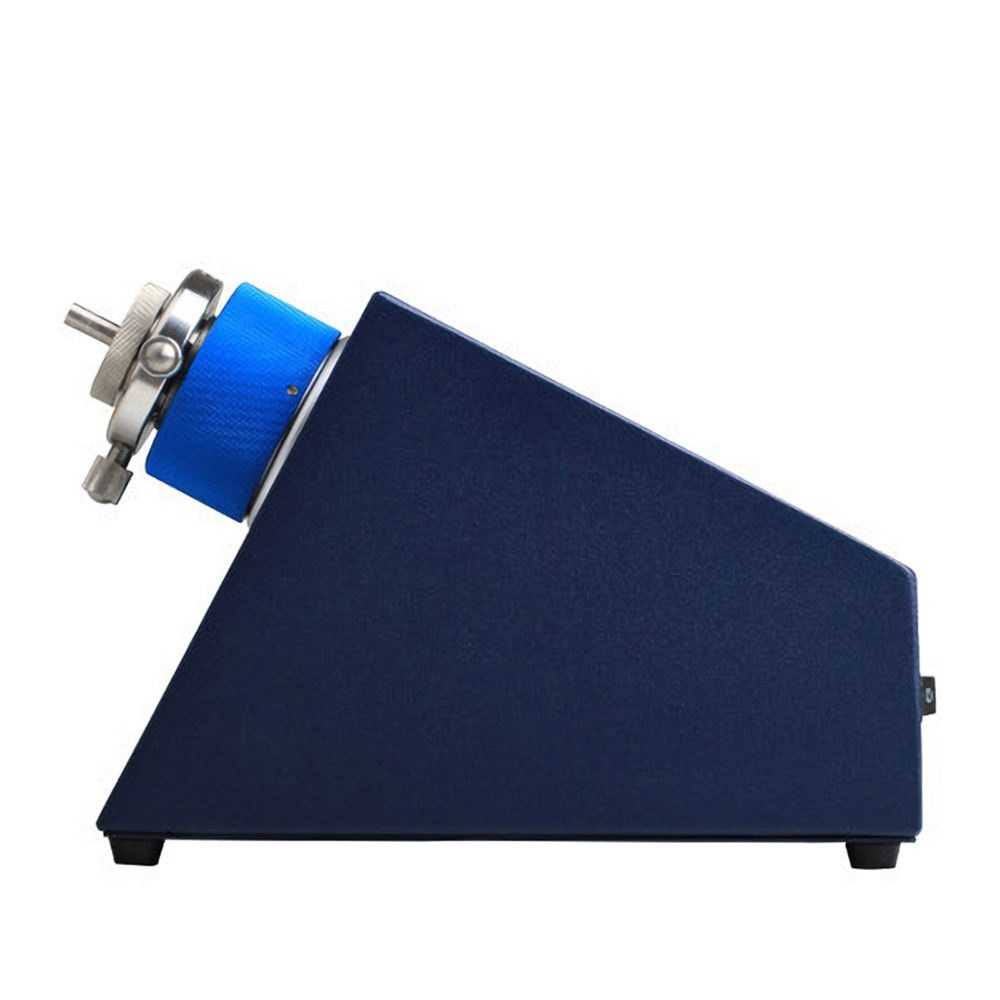

Product Features of interferometer Display Monitor:

- High Definition: Improved image quality for better inspection accuracy.

- Compact Size: Smaller footprint allows for easier integration into various workspaces.

- Flexible Operation: Enhanced usability with more adaptable operation modes.

- Integrated PC and APC Fixture:

- Patented design that allows inspection of both PC and APC fiber end-faces without the need to replace fixtures.

- Simplifies the inspection process and reduces the time and cost involved.

Inspection Capabilities:

- Connectors Supported:

- MPO (MTP) PC/APC Male/Female

- MT PC/APC Bare Ferrule

- 2.5mm Connectors: SC, FC, ST, E2000

- 1.25mm Connectors: LC, MU

- Other Types: CS, DIN, D4, MDC, LC Duplex

Technical Specifications of interferometer Display Monitor:

Benefits:

- Cost Efficiency: Reduces the need for multiple fixtures, saving costs.

- Improved Efficiency: Streamlines the inspection process, improving productivity.

- Versatile Applications: Suitable for a wide range of connector types and applications.

- User-Friendly: Easy to operate with manual focusing and high-definition display.