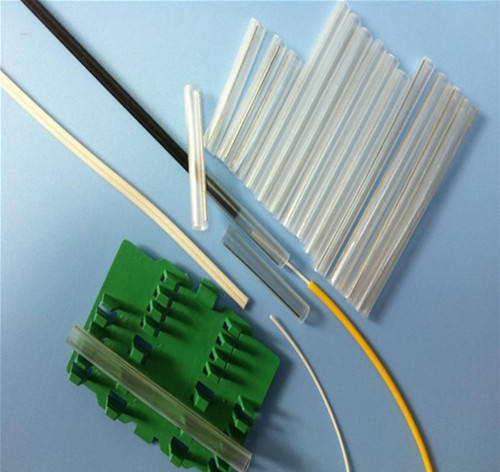

FTTH Drop Cable Description:

The FTTH Drop Cable Special 3.8mm Inner Diameter Splicing Sleeve 60mm is a specialized component used in Fiber to the Home (FTTH) installations, designed to protect and secure fiber optic splices.

Shrinkable sleeve is applied to the optical fiber closure to fix and protect the optical fiber when splicing.

The sleeve can be divided into two types(single and mass) according to the function. The single type is used for the single-fiber, and the mass type is used for the ribbon fiber. It is different in the reinforcement between two types. The single one realizes the reinforcement by the stainless steel needles, the later one via the ceramic reinforcement member to realize the function.

Key Features of FTTH Drop Cable:

- Inner Diameter: 3.8mm

- This inner diameter is designed to accommodate standard FTTH drop cables, providing a snug fit that ensures optimal protection and minimal movement of the fiber splice within the sleeve.

- Length: 60mm

- The 60mm length offers ample coverage for the spliced area, ensuring that the fusion splice and the surrounding fiber are well protected from physical damage and environmental factors.

Optical heat shrink protection for cable with fiber optic splice protection connection:

- Designed specifically for fiber splice protection elements

- Protect the connection point.

- Improve mechanical strength. this is the most reliable way to protect fusion.

- easy to use deburred and smooth stainless steel reducing the risk of fiber damage during installation.

- Transparent tube, it is easy to see the status of the optical fiber closure.

- shrinks temperature: 120ºC, shrink very quickly and very easy to install

Parameters:

| Shrinking Temperature (°C) | 110 ~ 130 |

| Radial Shrinking Rate (%) | >50 |

| Axial Shrinking Rate (%) | <10 |

| Low Temperature Property | No crackle at -55°C lasting 4 hours |

| Normal Operation Temperature (°C) | -55°C ~ + 135°C |

| Normal Operature Relative Humidity | ≤95% |

| Spark- over Strength (kV/mm) | ≥20 |

| Tensile Strength (Mpa) | 20 |

| Loss at -40°C | 0.03dB |

| Loss at +60°C RH95% | 0.02dB |

Applications:

- Use upgraded wire, hot melt tube and cross-linked polyolefin composition

- Rebuild the fiber covering

- junction to provide good mechanical strength

- Make sure the optical transmission properties are good

Features:

- Continuous operating temperature: -45°C~125°C;

- shrinkage temperature: start at 70°C; complete recovery at 125°C;

- Inner layer glue melting temperature: 70°C to 100°C;

- Shrinkage ratio:2:1,3:1,4:1

- Waterproof, RoHS compliant, flame retardant outer layer.