LSZH Optical Fiber Optic Overview:

LSZH Fiber optic drop cables are an important part of modern telecommunications and networking systems. They play a vital role in delivering high-speed Internet, phone service, and cable television to homes and businesses. In this blog, we’ll explore what are the main types of fiber optic drop cable and how to choose the right fiber optic drop cable.

In order to better understand this article, we first need to understand the concept of fiber optic drop cable.

Optical fiber drop cable is specialized cables used in telecommunications and networking. It is the final link in the fiber optic network and is typically laid aerially or buried. Drop cables are designed to be durable and flexible enough to handle outdoor installation and use rigors. They are also typically smaller and lighter than fiber optic cables, making them easier to install and maintain.

Application:

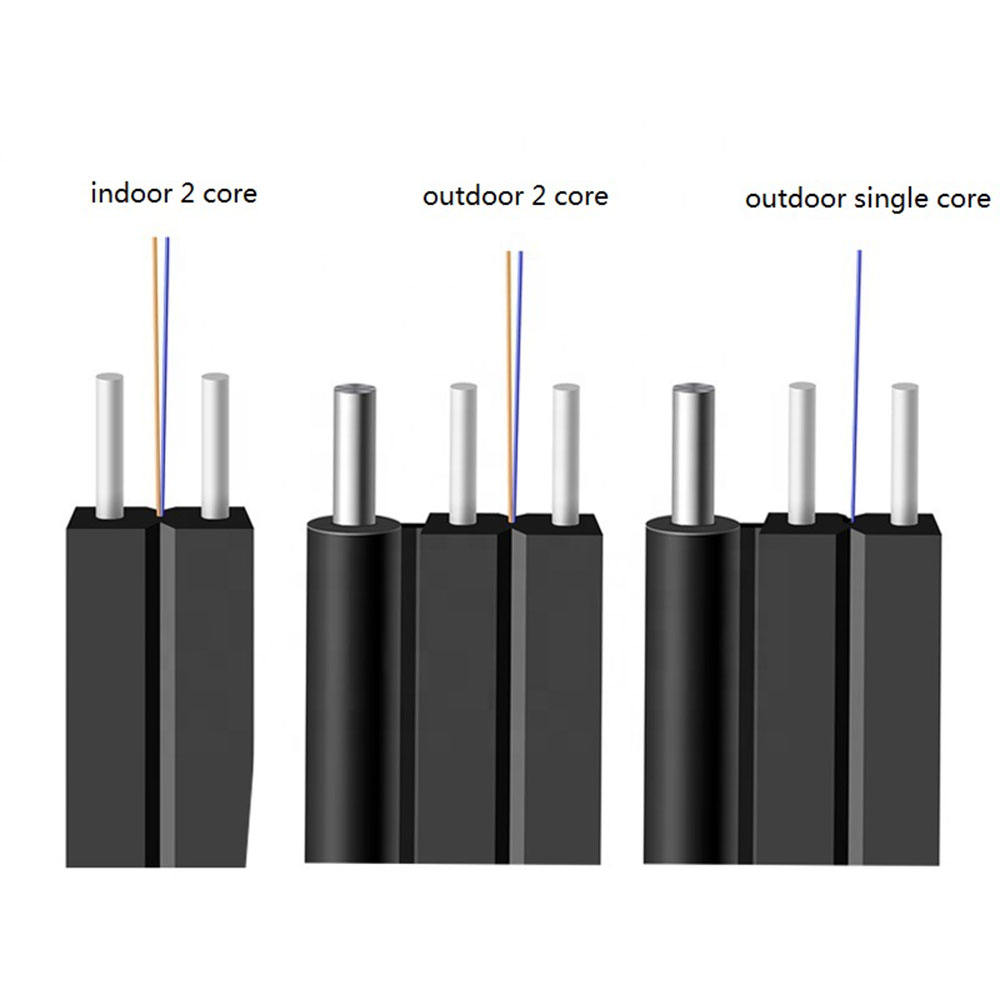

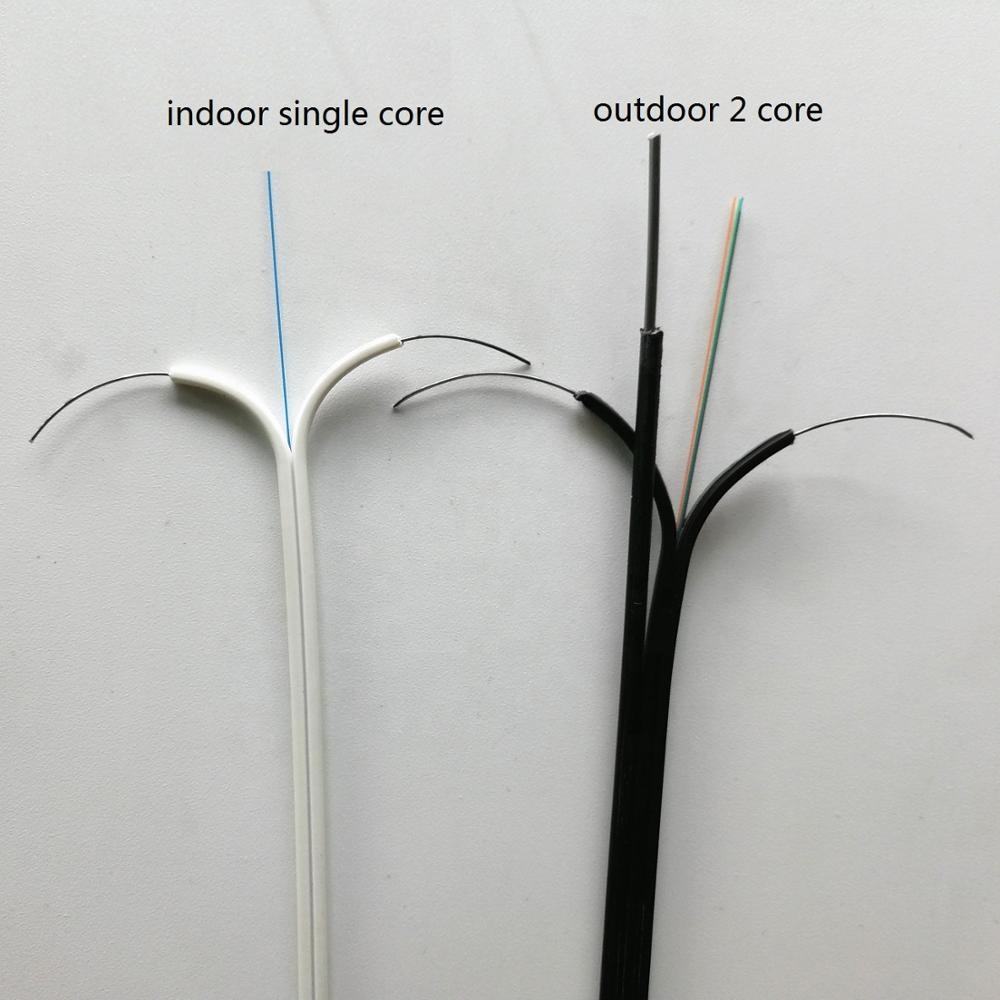

Indoor Use (GJXFH and GJXH): If you’re installing the cable indoors within a building, choose between Indoor FRP Drop Cable (GJXFH) or Indoor Steel Drop Cable (GJXH) based on your preference for flexibility and tensile strength. FRP cables are more flexible, while steel cables offer higher strength.

Outdoor Use (GJYXCH, Outdoor Flat Drop, Figure-8 Aerial, GYXTW): For outdoor applications, consider the type of installation. If it’s aerial between poles, opt for Figure-8 Aerial Drop Cable. For duct or aerial installations, choose Outdoor Steel Drop Cable (GJYXCH), Outdoor Flat Drop Cable, or Armored Duct/Aerial Drop Cable (GYXTW) based on your specific needs.

ASU (Access Service Unit) Applications: If you’re dealing with ASU installations in telecommunications access networks, ASU Optical Drop Cable is specifically designed for this purpose.

Environmental Conditions:

Indoor: FRP and steel drop cables are suitable for indoor environments. Consider FRP for more flexibility and easier routing.

Outdoor: Outdoor Steel Drop Cable, Outdoor Flat Drop Cable, Figure-8 Aerial Drop Cable, and Armored Duct/Aerial Drop Cable are designed for outdoor conditions, with varying levels of weather resistance. Choose one based on your specific outdoor installation requirements.

Tensile Strength:

If you require higher tensile strength, especially for outdoor installations where the cable might be subjected to mechanical stress, consider options like Steel Drop Cable (GJXH) or Armored Duct/Aerial Drop Cable (GYXTW).

Flexibility:

FRP Drop Cable (GJXFH) is a good choice for flexibility and ease of installation within indoor spaces.

Cost Considerations:

Different cable types come with varying costs. Consider your budget and the specific features you need for your application.

Resistance to Environmental Factors:

If your cable will be exposed to harsh weather conditions or UV radiation, choose cables designed for outdoor use, such as Outdoor Steel Drop Cable or Figure-8 Aerial Drop Cable.

Electromagnetic Interference (EMI):

Consider the susceptibility of the cable to electromagnetic interference. Indoor FRP Drop Cable is immune to EMI, while steel cables may be susceptible.

Installation Ease:

Some cables are easier to install than others. FRP Drop Cable is typically easier to route indoors, while outdoor cables may require more careful handling during installation.

In summary, choosing an appropriate optical fiber drop cable should be based on your specific installation requirements, including application, environmental conditions, performance needs, and budget constraints. Careful consideration of these factors will help you select the right cable type for your project.

Features:

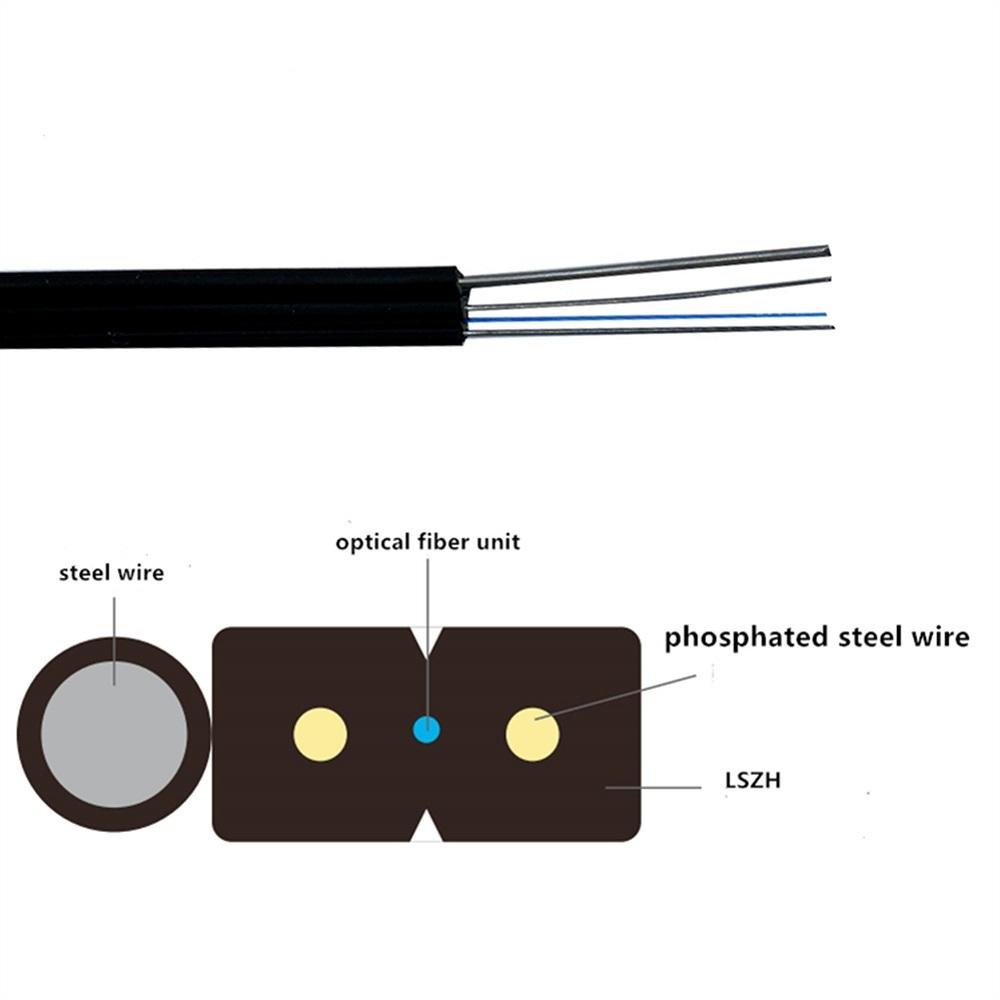

LSZH (Low Smoke Zero Halogen) optical fiber cables are designed with specific features to enhance safety and minimize environmental impact. Here are some of the key features typically associated with LSZH fiber optic cables:

- Halogen-Free: LSZH cables are manufactured without halogen compounds, such as chlorine and fluorine. This feature reduces the emission of toxic gases and corrosive substances when the cable is exposed to heat or fire, making LSZH cables safer for human health and the environment, especially in enclosed spaces like buildings and data centers.

- Low Smoke Emission: During a fire, LSZH cables produce minimal smoke compared to traditional PVC (polyvinyl chloride) cables. This feature improves visibility and allows for easier evacuation in emergency situations, reducing the risk of smoke inhalation and aiding firefighting efforts.

- Flame Retardant: LSZH cables are formulated to resist flames and combustion. They are designed to self-extinguish once the external flame source is removed, helping to prevent the spread of fire along the cable pathway.

- Corrosion Resistance: LSZH materials offer excellent resistance to chemical corrosion, ensuring the long-term reliability and performance of the cable, particularly in harsh environments where exposure to moisture or chemical agents is a concern.

- Environmental Compliance: LSZH cables are often manufactured in compliance with various environmental regulations and standards, such as RoHS (Restriction of Hazardous Substances Directive) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), which restrict the use of hazardous substances in electronic and electrical products.

- Mechanical Durability: LSZH cables maintain mechanical strength and durability comparable to traditional fiber optic cables, ensuring reliable performance in demanding applications and installation environments.

- Wide Application: LSZH cables are suitable for a wide range of indoor and outdoor applications, including telecommunications networks, data centers, industrial automation, transportation systems, and residential buildings, where safety, environmental protection, and regulatory compliance are essential considerations.

| Specification | Description |

|---|---|

| Cable Type | LSZH Optical Fiber Cable |

| Fiber Type | Single-mode (SM) or multi-mode (MM) |

| Fiber Count | Number of optical fibers within the cable |

| Fiber Category | G.652, G.657, OM1, OM2, OM3, OM4, OM5, etc. |

| Jacket Material | LSZH (Low Smoke Zero Halogen) |

| Jacket Color | Typically yellow, orange, aqua, or custom color |

| Outer Diameter (OD) | Diameter of the entire cable including the jacket |

| Tensile Strength | Maximum force the cable can withstand without breaking |

| Operating Temperature | Temperature range within which the cable can operate effectively |

| Flame Retardancy | Meets flame retardancy standards such as UL 1666, IEC 60332-3, or equivalent |

| Smoke Emission | Low smoke emission characteristics during combustion, typically compliant with standards like IEC 61034 and IEC 60754 |

| Halogen Content | Halogen-free construction, complying with standards such as IEC 60754-1 and IEC 60754-2 |

| Environmental Rating | Suitable for indoor and outdoor use, compliant with environmental regulations such as RoHS and REACH |

| Applications | Telecommunications networks, data centers, industrial automation, transportation systems, residential buildings, etc. |

| Compliance | Meets relevant industry standards and regulations (e.g., ANSI/TIA, ISO/IEC, Telcordia GR, etc.) |

| Warranty | Manufacturer’s warranty period for quality and performance assurance |

For more: Click here