Polishing Machine Patch Cord Description:

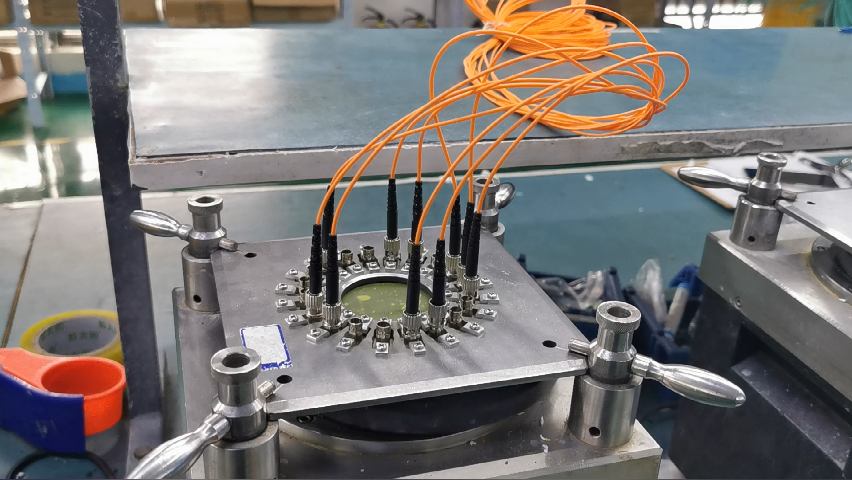

The Polishing Machine Patch Cord is engineered to polish various types of fiber optic connectors, including fiber optic patch cords, pigtails, and ribbon patch cords/pigtails. It is also effective for adding connectors to PLC splitters, energy fibers, glass fibers, and pre-terminal fast connectors. This polishing machine is an integral component of a fiber optic production line, often used alongside equipment such as fiber optic cable cutting machines, microscopes, heat ovens, crimping machines, insertion loss and return loss testers, and ultrasonic cleaners.

Product Features of Polishing Machine Patch Cord:

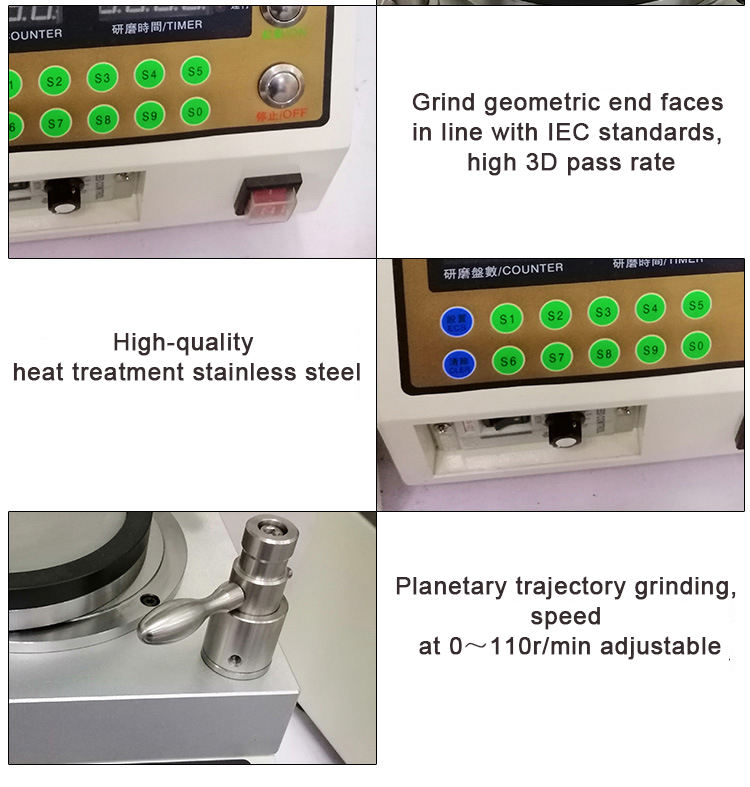

- Fiber Optic Connector Polishing: Specifically designed for high-precision polishing of fiber optic connectors.

- High Volume Manufacturing: Suitable for large-scale production environments.

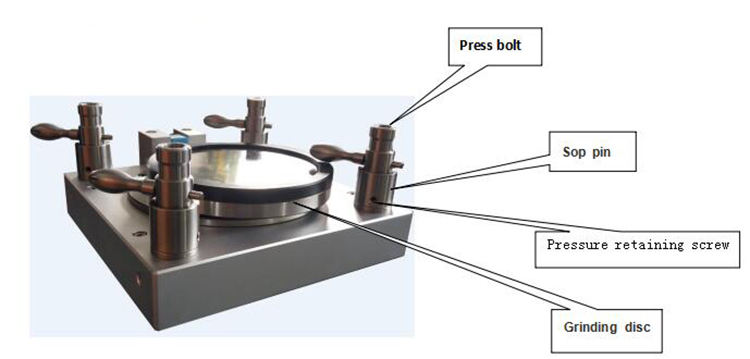

- Stainless Steel Polishing Plate: Provides reliability and stability.

- Quick Change Tooling: Facilitates efficient tool changes.

- APC Back Reflection: Achieves back reflection as low as -70 DB.

- UPC Back Reflection: Achieves back reflection as low as -60 DB.

- Insertion Loss: Typically around 0.2 DB.

- Super Centering Accuracy: Ensures high precision.

- Low Undercut: Minimizes connector undercut.

- Excellent Connector End face Polishing Quality: Delivers superior end face polishing results.

Performance Features

- Stainless Steel Polishing Plate: Ensures durability and stability.

- Double Motors: Provides sufficient power for operations.

- High Accuracy: Minimal plane tolerance for precise machining.

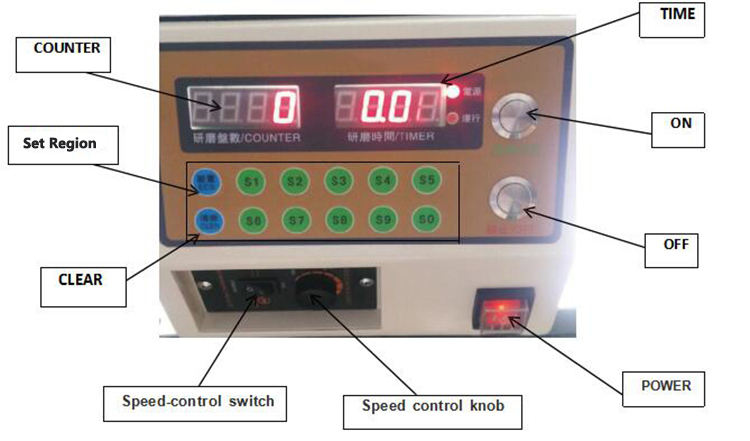

- Adjustable Rotation Speed and Time: Simple operation for flexibility.

- Excellent Stability: Long lifetime, typically five to ten years.

Specifications of Polishing Machine Patch Cord:

| Parameter | Details |

|---|---|

| Machine Size | 240mm x 240mm x 260mm |

| Outer Diameter of Rotation Plate | 127 mm (5 inches) |

| Time Settings | Up to 99 minutes and 99 seconds |

| Speed for Rotation Plate | 90 rpm |

| Height of Plate Jumpiness | <10 μm |

| Pressure Configuration | 21 ~ 36 N/cm² |

| Working Temperature | 10℃ ~ 40℃ |

| Relative Humidity | 15% ~ 85% |

| Noise | Less than 50 dB when unloaded |

| Vibration (Working Status) | 0.25g at 5~100Hz for 10 minutes |

| Vibration (Stopping Status) | 0.50g at 5~100Hz for 10 minutes |

| Power Input | 220~230 VAC, 50Hz/60Hz |

| Electric Power | 40W |

| Net Weight | 28 kg |

| Materials | Stainless steel |

The Fiber Optic Polishing Machine is an essential tool for ensuring the highest quality in fiber optic connector production, offering reliability, precision, and efficiency for high-volume manufacturing environments.