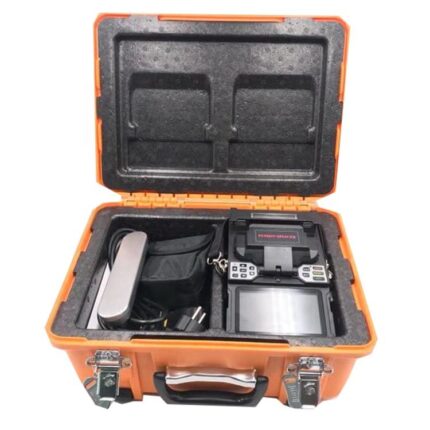

X-800 Fusion Splicer Description:

An X-800 Fusion Splicer is a crucial device used in the field of fiber optic communications. It is designed to join two optical fibers end-to-end using heat. The goal is to fuse the fibers in such a way that light can pass through with minimal loss and reflection, ensuring efficient signal transmission. A fiber cleaver is an essential accessory for the fusion splicer, as it prepares the fiber ends for splicing by making precise and clean cuts.

Key Features:

- ★Core Alignment Fusion Splicer★ – X-800 Fusion Splicer is a core alignment fiber fusion splicer with advanced image processing technology; to ensure high-precision fiber core-to-fiber core alignment and splicing, it adopts high-precision CMOS camera, optical system and servo system; and use high-precision CNC machining of optical fiber mounting clips, V-shaped grooves and other metal parts.

- ★ Fast Connecting and Heating ★ – The X-800 Fusion Splicer welding machine uses a powerful high-speed motor and a powerful CPU, which can achieve a fast connecting time of 6 seconds and a heating time of 13 seconds (fast mode), which improves the work of the engineer Efficiency significantly improves; Optical Fusion Splicer is very suitable for data center, Metro, LAN and FTTT x fiber projects.

- ★4.3 inch touch screen design and durable appearance design ★ – optical fiber fusion splicer is equipped with a 4.3 inch TFT touch screen, which is easy and intuitive to operate. The X-800 Fusion Splicer optical fiber fusion splicer adopts a lightweight and sturdy aluminum alloy shell and an integrated silicone protective cover, making it impact resistant, windproof, waterproof and dustproof, to meet the demands of various harsh environments.

- ★Automatic Function Design ★ – Optical Fusion Splicer can automatically monitor environmental conditions (such as temperature, air pressure and humidity) and perform automatic arc compensation to compensate for these environmental effects. And it also has auto focusing, auto welding, auto heating, auto correction and other auto functions.

- ★ Splicing evaluation function ★–After the fiber splicing is completed, SS414F can perform splicing loss evaluation and tensile test to check the splicing point and mechanical stability (must be opened in the settings). Even using different fibers or fibers with high core eccentricity, excellent splicing results can be obtained.

- ★5PARS of electrodes+ Fiber cleaver+ Fiber tool set ★ – We have equipped users with a wealth of accessories, allowing users to immediately perform high-precision fiber cleavage; 5PARS of electrodes can perform 5*8000 high-quality splicing operations; The fiber chopping blade has a 16-point tungsten gold blade, which can cut 48,000 times; 11.1V 4000mah lithium battery can perform 300 times of Optical Fusion Splicer or shrink tube heating.

Specifications of X-800 Fusion Splicer:

|

Model

|

X-900 Core Alignment Fusion Splicer

|

|

Applicable fiber

|

SM(ITU-T G.652),MM(ITU-T G.651),DS(ITU-T G.653),NZDS(ITU-T G.655), EDFA, others(including G.657)

|

|

Diameter of cladding

|

80 -150μm

|

|

Diameter of coating

|

160-900μm

|

|

Typical splice loss

|

SM: 0.02dB, MM: 0.01dB, DS: 0.04dB, NZDS: 0.04dB

|

|

Return loss

|

> 60dB

|

|

Fibe cleaved length

|

5-16mm ( coating diameter < 250um), 16mm (coating diameter:250-1000um)

|

|

Splicing program

|

40 groups

|

|

Operate mode

|

Automatic/Manual

|

|

Auto-heating

|

Available

|

|

Typical splicing time

|

6 seconds

|

|

Typical heating time

|

18 seconds for 60mm and 40mm shrinkable sleeves

|

|

Fiber magnification

|

250X (X or Y view), 125X (X and Y view)

|

|

Display screen

|

2 CMOS cameras, 5.0 inch color LCD monitor

|

|

Records storage

|

5000 groups data and 100 groups image

|

|

Loss evaluation

|

Available

|

|

Tension test

|

>2.2N

|

|

Interface

|

GUI menu interface, easy for operation

|

|

Battery

|

5200mAh Li-battery, typical 300 cycles splicing and heating, support separating charging, operating time more than 5 hours,

discharging time more 8 hours |

|

Power supply

|

Adapter, input: AC 220±30V(50/60HZ), output: DC 12±2V

|

|

Electrodes life

|

More than 5000 ARC discharges, can be replaced conveniently

|

|

Terminal

|

USB2.0 port, for uploading splicer results and upgrading software

|

|

Operating conditions

|

Altitude: 0-5000m, Humidity: 0-95%,Operating Temperature: -25℃~+50℃, Storage temperature -40℃~+80℃;Wind speed: Max 15m/s

|

|

Dimension

|

156mm(L) * 141mm(W) * 156mm(H) (including rubber armor)

|

|

Weight

|

2.45kg (including battery)

|

|

Standard Accessories

|

1. Main machine with battery inside 2.Carrying Case 3.X-50B for X-900 splicer

4.Fiber miller stripper 5.Drop cable stripper 6.Cooling tray 7.Power adapter 8.Power cord 9.Spare electrodes 10.USB user manual 11.Strap 12. Alcohol pump |