Overview of Automatic Fiber Optical WL-S1 Fusion Splicer

The Automatic Fiber Optical WL-S1 Fusion Splicer is a state-of-the-art device designed for joining optical fibers end-to-end using advanced fusion splicing technology. This splicer is engineered to deliver high precision, efficiency, and reliability, making it an essential tool for professionals in the telecommunications, data centers, and fiber optic network maintenance sectors.

Key Features

- Core Alignment Technology:

- Utilizes advanced core alignment (PAS) technology for precise alignment of the fiber cores before splicing.

- Ensures minimal splice loss and high-quality joints.

- Automated Splicing Process:

- Fully automatic splicing process, reducing the need for manual intervention and increasing efficiency.

- Features automatic fiber detection, alignment, splicing, and loss estimation.

- High-Resolution Display:

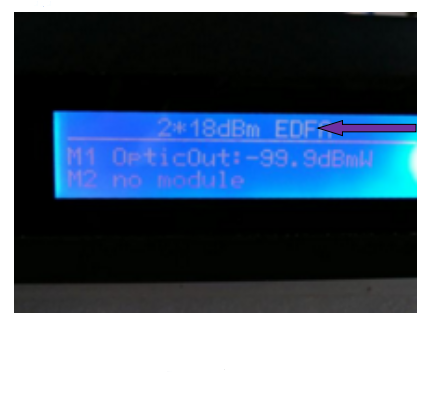

- Equipped with a high-resolution color LCD screen that provides a clear view of the splicing process.

- User-friendly interface for easy operation and monitoring.

- Fast Splicing and Heating:

- Quick splicing time, typically under 10 seconds.

- Fast heating time for splice protection sleeves, usually under 30 seconds.

- Built-in Battery:

- Includes a built-in rechargeable battery, providing flexibility for fieldwork and remote operations.

- Long battery life, capable of performing multiple splices on a single charge.

- Rugged Design:

- Durable and compact design, suitable for various working environments, including harsh outdoor conditions.

- Shock-resistant and dust-proof construction.

- Data Storage and Connectivity:

- Internal memory to store splice data and images.

- USB and SD card interfaces for data transfer and software updates.

Splicing Process

- Fiber Preparation:

- Strip the protective coating from the fiber ends using a fiber stripper.

- Cleave the fibers using the included precision fiber cleaver to ensure clean, flat ends.

- Clean the cleaved ends with alcohol wipes to remove contaminants.

- Fiber Loading:

- Load the prepared fibers into the splicer’s fiber holders.

- The WL-S1 automatically detects and aligns the fibers.

- Fusion Splicing:

- WL-S1 Fusion Splicer uses an electric arc to melt and fuse the fiber ends.

- Automatic estimation and display of splice loss on the LCD screen.

- Splice Protection:

- Apply a heat shrink sleeve over the splice.

- The splicer’s built-in heater quickly shrinks the sleeve, protecting the splice.

Applications

- Telecommunications: WL-S1 Fusion Splicer Ideal for building and maintaining high-speed fiber optic networks.

- Data Centers: Ensures reliable and efficient data transmission within data centers.

- Cable Television: Essential for the installation and upkeep of fiber optic cables in cable TV networks.

- Industrial and Military: Suitable for robust and reliable fiber connections in industrial settings and military communications.

Advantages

- Precision and Low Loss: WL-S1 Fusion Splicer Core alignment technology ensures high-quality splices with minimal loss and reflection.

- Efficiency and Speed: Automated processes and quick splicing times increase productivity.

- Durability: Rugged design allows for reliable performance in various environments.

- Flexibility: Built-in battery and compact size make it ideal for fieldwork.

| Explore More: |

| Fiber optic splicing machine |

| Splicing Machine 6 motors |

| A-87S Fusion Splicer |

| A-80S Fusion Splicer |

| X-800 Fusion Splicer |